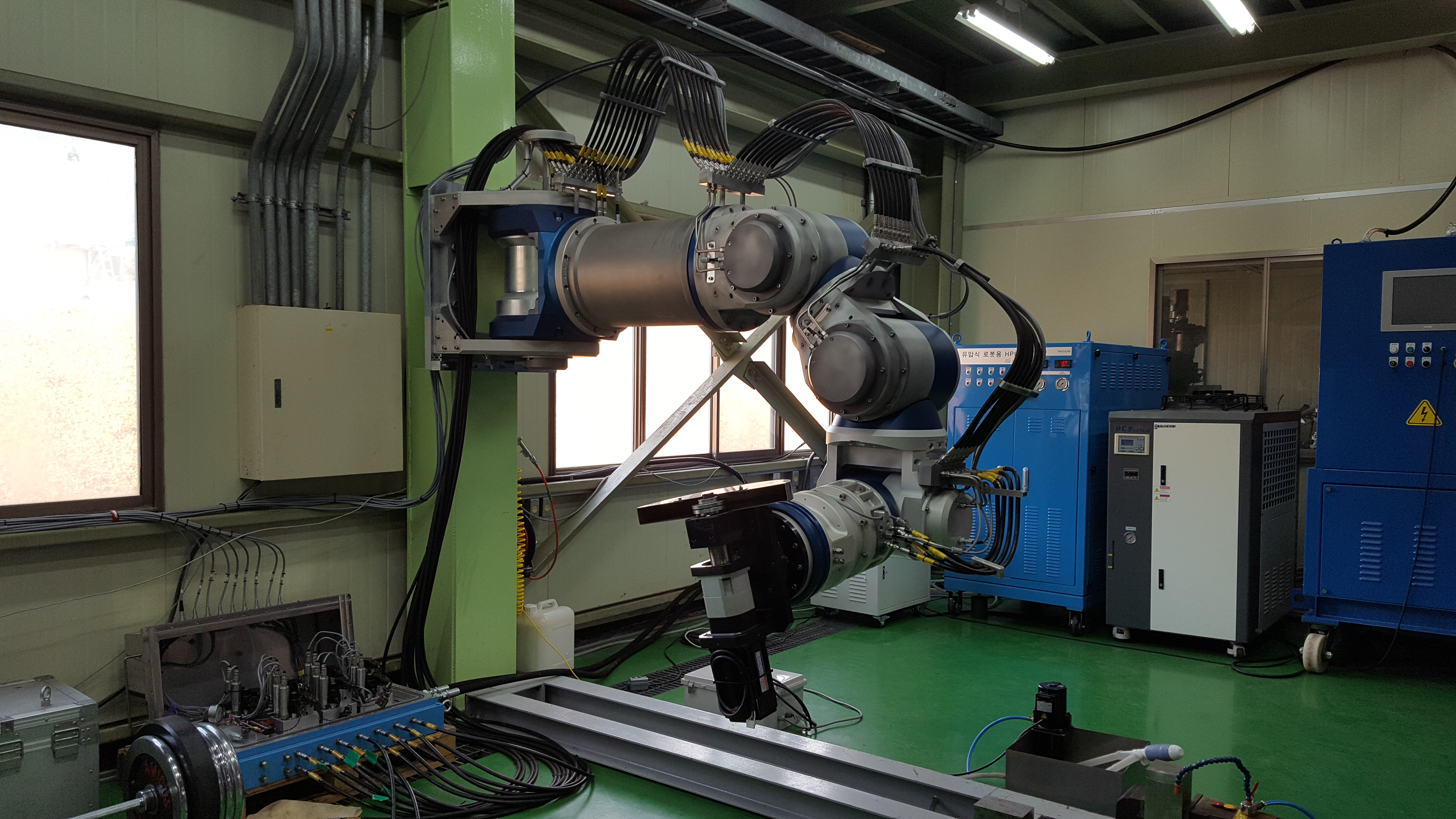

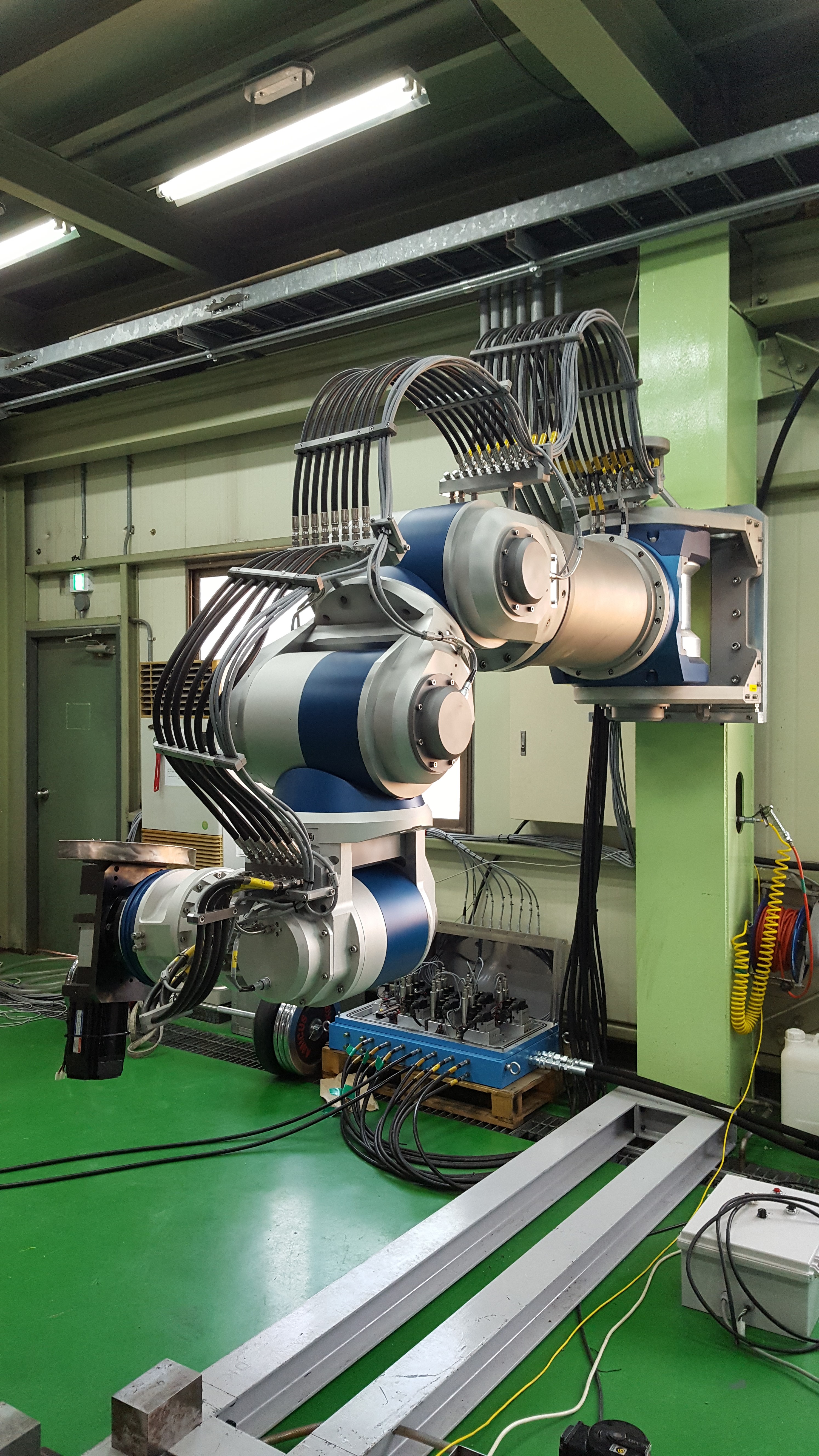

Heavy-Duty and Hing-Precision Hydraulic Manipulator for Decommissioning Nuclear Power Plants (KAERI(Korea Atomic Energy Research Institute))

Heavy-Duty and Hing-Precision Hydraulic Manipulator for Decommissioning Nuclear Power Plants

- Policy features

A dismantling robot is needed to improve the safety of workers and shorten the dismantling work time to improve economic efficiency during nuclear power dismantling work. In particular, during the dismantling work, it is difficult for workers to transfer a heavy object or perform a precise cutting operation. Therefore, we developed a hydraulic manipulator for disassembly that can continuously operate without failure during long-term disassembly work and maintain high precision when handling heavy objects.

- Policy details

- Government Organization Information

- Other Policys of

this Government Organization - Related recommended policys

Policy details

When dismantling a nuclear power plant, the most difficult task is cutting the reactor vessel with high radioactivity. In foreign countries, there are many cases of dismantling work using a lot of dedicated equipment. Dedicated equipment was developed for specific tasks. However, it takes a lot of time to install dedicated equipment, and it takes a lot of time to replace it with other dedicated equipment for other work. So, rather than using dedicated equipment, we need a dismantling robot that can be used for multiple purposes. Therefore, it is believed that the use of a dismantling robot can increase the safety of workers in the dismantling work and shorten the dismantling work time, thereby improving economic efficiency.

During the dismantling work, heavy objects must be transported and the cutting work must be performed precisely. The dismantling robot must be capable of continuously transferring heavy objects and performing precision cutting work in a high radiation area without interruption of work due to failure for a long time.

Even in foreign cases, there are cases in which the dismantling work is performed using a dismantling robot. There is no dismantling robot that can perform precision cutting while handling heavy objects underwater and in a high radiation environment. In particular, there is no case of a dismantling robot that is generally used in the reactor dismantling process. In some cases, a process delay occurs in the repair process due to a breakdown of the dismantling robot.

The dismantling robot to be developed by this research center can cut with a precision of 1mm while handling 250kg heavy objects in an underwater 30m and high radiation environment. Therefore, economic feasibility can be improved by shortening the working time and reducing the generation of by-products.

We are striving to improve reliability to ensure continuous operation without failure during long-term dismantling work, and we will conduct research to increase the practical use of nuclear power plant dismantling work through a suitability test for dismantling work in a mockup facility.

The dismantling robot is composed of a module. If it is configured in a module form, it is easy to change the shape of a suitable robot according to the dismantling operation, so it can be used in other dismantling processes besides the nuclear reactor cutting operation.

In the future, it can be used in other industries besides dismantling work.

- Policy details

- Government Organization Information

- Other Policys of

this Government Organization - Related recommended policys

Government Organization Information

Address : 111, Daedeok-daero 989beon-gil, Yuseong-gu, Daejeon, 34057 Republic of Korea

Website : http://www.kaeri.re.kr

Since its establishment in 1959, KAERI has been the only research institute in Korea dedicated to nuclear energy. Over the past 60 years, it has accelerated developments in nuclear technology and made significant achievements, including the localization of PHWR and PWR reactors, the design of a Nuclear Steam Supply System(NSSS) - applied to Uljin Units 3 & 4 - and the design and construction of the multi-purpose research reactor HANARO.

As the first research institute of science and technology in Korea and one of the world's best centers of nuclear research, KAERI is building a safe society centered on people and the environment. It will continue to expand into new fields, improving quality of life while attaining higher standards in safety and reliability.

Other Policys of

this Government Organization

- Policy details

- Government Organization Information

- Other Policys of

this Government Organization - Related recommended policys