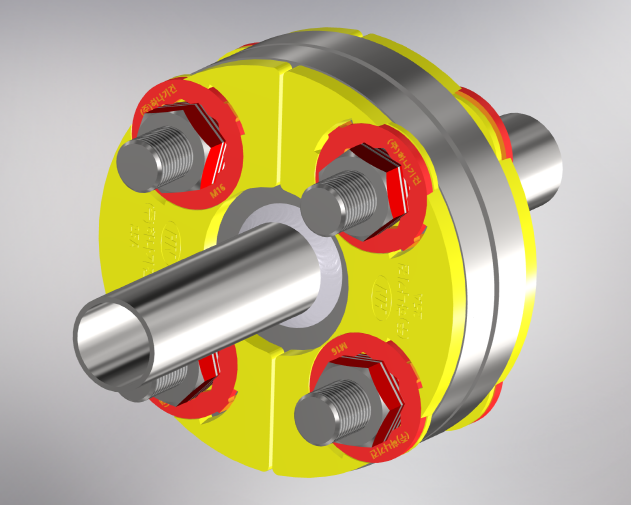

Seismic resistance GD damper (4M CO.,LTD)

Seismic resistance GD damper

- HS Code

- Certification

- Patent

- Awards

- Features

Buckling Confined Steel Damper Solves Problems with Existing Panel-type Steel Damper

1. Stable Lateral Load-Transverse Relationship

2. Prevention of Exterior Buckling by Steel Composition

3. Effective stiffness and strength reinforcement

4. Superior damping performance

5. Superior energy absorption and minimal pinching

Product details

Key point: Confinement of outside-surface buckling, constructionability, minimization of finish removal, and certainty of lightening

* Overview of technology

Stiffness and energy-dissipating type seismic resistant steel construction method consisting of X-shaped steel core plate and addition dam plate

consisting of an X-shaped core plate of steel that increases the effectiveness of the stress distribution and a thick dam plate that effectively constrains the possible Buckling of steel in the compression zone.

Seismic reinforcement method that increases stiffness for shear loads and can efficiently dissipate repetitive energy generated from seismic loads The technology consists of X-shaped steel core plate and addition dam plate, which acts as a reinforcement for stiffness until the yield displacement occurs, and operates as a damper after the yield displacement occurs.

A technique for effectively preventing the Buckling of the Deep Plates in the case of capitulation of steel on the shear by using a cover dam plate.

Seismic capability of the rigid and energy-dissipating type seismic resistant steel technology for stable hysteresis behavior is excellent, and construction performance is also excellent.

* Excellence in technology

1. In the case of an existing earthquake-resistant system, it was common to install it during the construction stage of a building, and it was not easy to construct it in the future for reinforcement of existing construction structures.

Solving problems such as excessive cost and serious damage to the exterior of a structure when constructing a dust-proofing system

2. Solving the problems that arise when the level of expected seismic loads is not effective, and the intention of installing the damper of the structure is lost and the control function of the structure is not properly exercised.

3. Effective structural re-modeling with one or two existing special devices (dampers) for exterior design of building structures that require aesthetic functions as well as the above problems

The biggest feature is that it can dramatically improve design freedom, which was very limited to achieving effects.

* Seismic prevention technology: A vibration-proofing device using a Buckling-bound Steel Damper to prevent out-of-plane Buckling, which is a disadvantage of steel, to prevent compression stress degradation

* Seismic reinforcement technology: A damper acts as a stiffening role before a certain displacement occurs and after a constant displacement occurs.

* Constructionability enhancement technology: It can be installed internally and externally without removing existing walls, minimizing demolition costs.

* Economic efficiency improvement technology: Buckling steel dampers are shear yield type, and no cost personnel are used for maintenance after installation.

* aesthetic improvement technique: excellent aesthetic and lighting as it is installed as wall or window between columns.

* New technology

- Effective prevention of Buckling in the case of surrender of steel by shear

- The hysteretic behavior of the structure can reduce the demand curve by calculating the attenuation ratio.

- It acts as a stiffening force before a certain displacement occurs, and as a damper after a certain displacement occurs.

- Give me the old wall without removing it.It can be installed externally to minimize demolition cost.

* Features of technology

- Damper system, unlike conventional damper products, effectively improves the ability to remove a structure without compromising the appearance of the structure

- Effective absorption of various seismic energy from stiffness and energy-dissipating capacity reinforcement and flexibility in existing building systems

Buckling-bound Seismic Retrofit Method Using Corresponding Steel Frames

- Optimal seismic reinforcement method that has excellent construction capability and is advantageous for securing seismic performance at low cost

* Construction sequence

1. Demolition of finishing materials in the installation location - > 2. Attachment surface treatment - 3. 3. Anchorhole work and fixation - 4. 4.

Epoxy injection and sealing - 5. 5. Damper frame installation and fixation

Company Information

Address : 50, Gwangpo 3-gil, Gwangyang-si, Jeollanam-do, Republic of Korea

Website : http://www.four-m.co.kr